Unlock Cost-Effective Solutions: Aftermarket Construction Parts for Every Project Requirement

Unlock Cost-Effective Solutions: Aftermarket Construction Parts for Every Project Requirement

Blog Article

Maximize Performance: The Advantages of Making Use Of Aftermarket Parts for Heavy Machinery

In the world of hefty equipment maintenance and optimization, the use of aftermarket components has actually emerged as a critical choice for numerous sector specialists. The decision to integrate aftermarket components right into hefty equipment elevates relevant concerns around efficiency improvement, cost-effectiveness, and lasting functional performance. As industries remain to seek ways to elevate the performance and toughness of their hefty tools, the conversation bordering the advantages of aftermarket components comes to be increasingly compelling. By exploring the subtleties of this different strategy to equipment upkeep, one can reveal a world of possibilities that provide greater than meets the eye.

Affordable Service

A cost-effective strategy to maintaining heavy equipment is by opting for aftermarket parts, which supply an affordable option without endangering high quality. Aftermarket components are manufactured by third-party business as replacements for initial equipment maker (OEM) parts.

Variety of Options

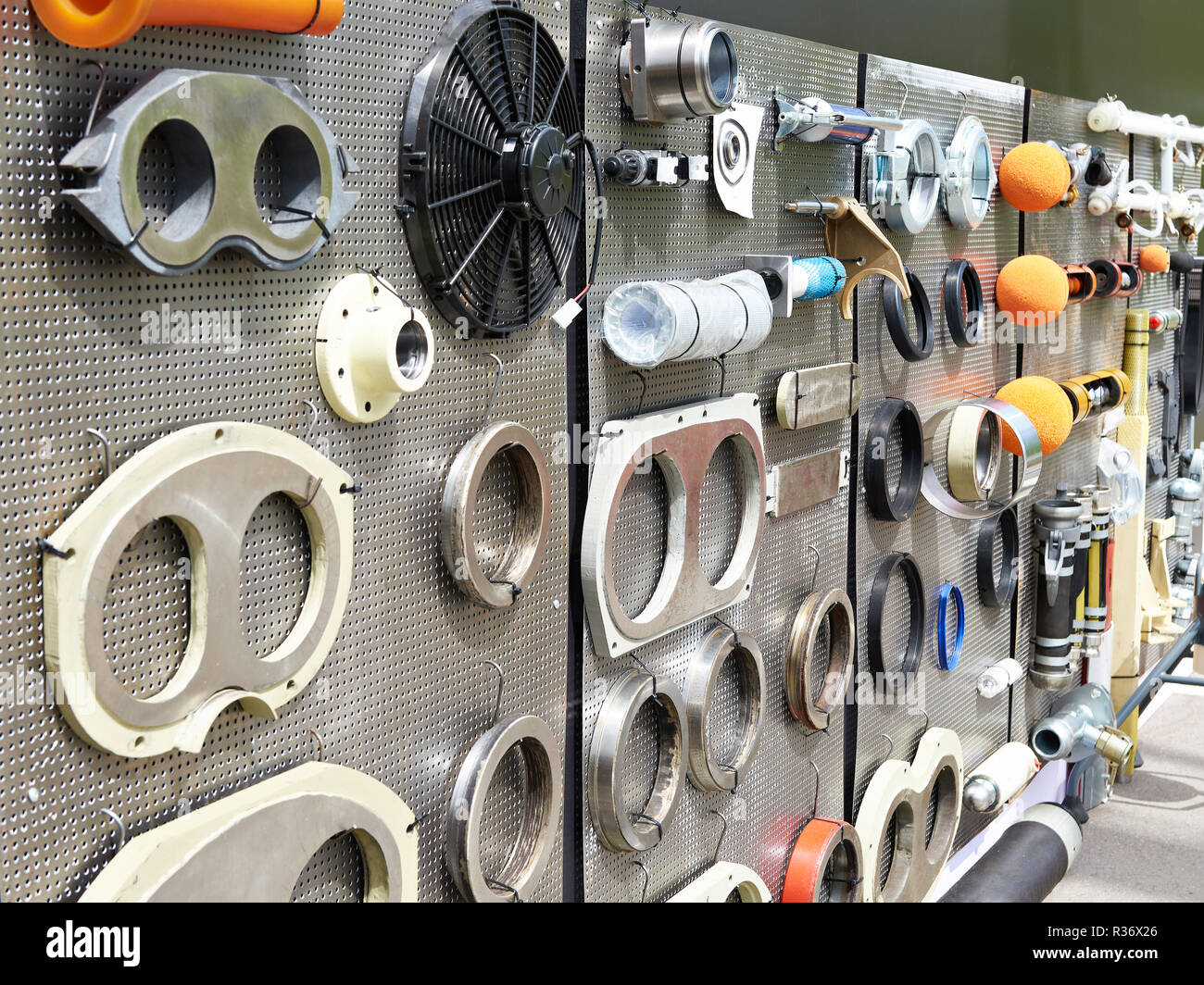

In addition, the schedule of aftermarket components from multiple providers and makers produces an open market that drives technology and top quality enhancement - aftermarket construction parts. This competitors advantages businesses by offering them access to technically innovative parts that might not be available from initial equipment suppliers (OEMs) By having a large range of aftermarket choices to pick from, organizations can optimize the efficiency, performance, and longevity of their hefty equipment while maintaining prices in control

Improved Efficiency and Effectiveness

Enhancing heavy machinery performance and efficiency via the usage of aftermarket parts is a tactical method that numerous businesses are increasingly taking on. By including aftermarket components specifically designed for hefty equipment, business can considerably enhance the total capability and efficiency of their equipment. Aftermarket parts usually use sophisticated technology and boosted products compared to initial devices manufacturer (OEM) components, resulting in enhanced efficiency levels.

One trick aspect of aftermarket components contributing to boosted efficiency is their capacity to attend to specific concerns or weaknesses click to find out more in the initial machinery style. This targeted approach can cause better general functioning, minimized downtime, and increased functional efficiency. In addition, aftermarket parts are regularly engineered to give better longevity and durability, more boosting the equipment's efficiency over an extended duration.

In addition, aftermarket parts can assist maximize the machinery's fuel intake, leading to cost financial savings and ecological benefits. By fine-tuning the equipment's elements, organizations can achieve higher levels of effectiveness, converting into improved success and sustainability in the future. In conclusion, leveraging aftermarket parts to improve heavy equipment efficiency and performance can supply a competitive edge in today's demanding industrial landscape.

Enhanced Personalization Opportunities

Structure upon the boosted efficiency and imp source effectiveness accomplished with aftermarket components, heavy machinery operators can currently check out boosted modification opportunities to more maximize their tools. By including aftermarket components that provide to details demands, drivers can adjust their machinery to do jobs a lot more effectively and successfully. These personalization choices variety from enhanced engine components to specialized add-ons that accommodate one-of-a-kind task demands. Operators can mount custom-made exhaust systems to enhance airflow and increase engine performance, or they can opt for specialized pails and blades that are tailored to the kind of product being dealt with. In addition, aftermarket components offer the adaptability to change various facets of the machinery, such as hydraulic systems, controls, and safety attributes, enabling a personalized strategy to devices optimization. This increased personalization not only improves the performance of heavy equipment however additionally makes sure that drivers can adapt their tools to satisfy the specific needs of different jobs, ultimately causing better efficiency and cost-efficiency.

Extended Equipment Life Expectancy

By making use of aftermarket parts especially designed for heavy equipment, equipment owners can dramatically prolong the life of their makers (aftermarket construction parts). These components can enhance the efficiency of hefty machinery, leading to smoother this page procedures and lowered wear and tear on vital parts.

Aftermarket components use an economical option compared to original tools maker (OEM) parts, allowing tools proprietors to preserve their devices at a lower price without endangering high quality. Additionally, the availability of a vast variety of aftermarket parts makes it less complicated to locate appropriate replacements for numerous machinery versions and brands, further sustaining the durability of heavy equipment.

Final Thought

To conclude, making use of aftermarket parts for hefty machinery supplies an economical service with a vast array of options that can improve performance and effectiveness. These parts likewise permit boosted customization possibilities and can add to extending the life-span of the machinery. Generally, incorporating aftermarket parts right into heavy machinery repair and maintenance methods can take full advantage of efficiency and optimize operational end results.

Aftermarket components are manufactured by third-party business as substitutes for original equipment maker (OEM) components. Additionally, aftermarket parts come in various rate arrays, attributes, and qualities, enabling services to select the components that ideal match their spending plan and efficiency requirements.

Aftermarket parts commonly supply innovative technology and improved products contrasted to initial tools supplier (OEM) components, leading to improved efficiency levels.

Report this page